| email: enquiries@starcastalloys.co.uk telephone: 01837 851694 |

|

| HomeContact & Find us | |

|

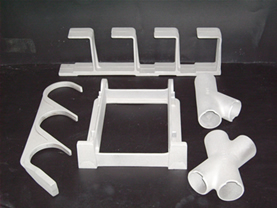

Pattern making, toolmaking, prototype castings through to fully machined components. From 1 to 1,000 (Green sand and resin bonded sand moulds). Aluminium sand and gravity die castings to the following specifications BS1490, LM4, LM6, LM25, also L99 and LM31, subject to component characteristics and quantity. Individual casting weights up to maximum of 75kg. Where required castings can be fully heat treated. Bronze and brass sand castings in the following specifications, BS1400, LG2, LG4, PB1, PB2, AB1, AB2, HTB1, and CMA2. Individual casting weights to a maximum of 100kg. Zinc castings to specification ZA12. We currently supply components to a wide range of industries, including fittings for marine equipment and offshore structures, where strength and corrosion resistance are the main criteria. Electrical contacts, brush holders, mounting brackets and cable clamps for use in power and rail network installations and the isolation or conductivity are essential. Valves, pump bodies and impellers for use in fluid management for both water and petro-chemical applications. Approved supplier to various M.O.D. sub-contract engineers. Various gears, bearings, pulleys, levers and manifolds for the general engineering industries. Structural, decorative and ornamental castings such as balustrades, railings, grilles, panels and plaques. Individually manufactured to customer requirements. Where machined casting are required we have comprehensive facilities in both CNC and conventional machining available. Finishing treatments such as powder coating, polishing and electroplating are available. |

|